Venting your tankless water heater is essential to ensure it operates safely and efficiently. Proper venting allows combustion gases to exit your home while bringing in fresh air for the burner, preventing dangerous buildup of carbon monoxide. Incorrect venting can lead to poor performance, increased energy costs, or serious safety risks.

There are mainly two types of venting methods to consider: direct venting, which draws air from outside and vents exhaust outdoors, and power venting, which uses a fan to push exhaust gases out. Understanding these options will help you choose the best setup for your space and comply with local codes.

If you’re near Anaheim, CA, Splash Plumbing can help guide you through choosing and installing the right venting system for your tankless water heater. Their experience in Orange County ensures your unit is safely vented and performing at its best. Learn more about venting a tankless water heater to protect your home and get reliable hot water whenever you need it. For detailed guidance, check this how to vent a tankless water heater guide.

Understanding Venting for Tankless Water Heaters

Proper venting is essential to ensure your tankless water heater runs safely and efficiently. It controls how combustion gases are expelled and affects the heater’s overall performance and lifespan. Understanding the purpose and risks involved will help you maintain optimal operation and protect your home.

Why Venting Is Necessary

Venting removes harmful combustion gases, such as carbon monoxide, produced during the heating process. Without proper venting, these gases could accumulate indoors, posing serious health risks.

A tankless water heater relies on continuous airflow to maintain combustion efficiency. This airflow improves fuel use, reduces wear on the unit, and supports consistent hot water delivery.

Because tankless heaters operate differently than traditional units, their venting requires specific designs to match the high-efficiency combustion system. Using the wrong venting can cause blockages or poor performance, which may increase energy use and shorten the heater’s life.

How Combustion Gases Are Managed

Tankless water heaters typically use either direct vent or power vent systems to handle combustion gases. A direct vent draws air from outside your home and exhausts gases outdoors, preventing indoor air contamination.

Power-vent models incorporate a fan to actively expel exhaust through a vent, which allows more flexible vent placement. Both methods aim to keep combustion gases moving safely out of your property.

In many cases, vents are installed horizontally or vertically depending on your home’s layout and local building codes. Ensuring proper sealing and materials in vent pipes is crucial to avoid leaks and maintain system integrity.

Risks of Improper Venting

If your tankless water heater is not vented correctly, you risk toxic gas buildup inside your home, which can lead to carbon monoxide poisoning. This is a significant safety hazard that can cause serious illness or death.

Poor venting also reduces the heater’s efficiency, leading to higher energy consumption and increased utility bills. It may cause your unit to shut down unexpectedly or fail prematurely due to overheating or corrosion from trapped exhaust.

Maintaining proper venting helps avoid costly repairs and ensures compliance with safety standards. For reliable installation or troubleshooting, a trusted professional like Splash Plumbing can assess and optimize your venting system to protect your home and family.

For more detailed guidance on venting options and best practices, see how to vent a tankless water heater effectively at this detailed venting guide.

Types of Tankless Water Heater Venting Systems

Understanding the different venting systems is crucial to ensuring your tankless water heater operates safely and efficiently. Proper venting affects installation options, system performance, and long-term reliability.

Direct Vent Systems

Direct vent systems draw air from outside your home and expel exhaust gases directly to the outside through two separate pipes. This setup prevents the mixing of combustion gases with indoor air, making it a safe option for indoor installation.

You can install direct vent units horizontally or vertically, depending on structural layout. This system improves efficiency by using outdoor air for combustion, helping reduce drafts or pressure imbalances inside the house. If you’re in an area with strict building codes, direct venting is often required for compliance and safety.

Power Vent Systems

Power vent systems use an electric blower to push exhaust gases through the vent pipe. This allows greater flexibility in vent pipe length and routing, as exhaust can travel further horizontally or vertically without the need for multiple chimney shafts.

These systems require a nearby electrical outlet to operate the blower. Power venting can help when direct venting is impractical due to building structure or required vent length. However, blower noise and electrical dependency are considerations to keep in mind. Power vent systems maintain safe indoor air quality by expelling combustion gases efficiently.

Concentric Vent Systems

Concentric venting combines both intake and exhaust pipes into a single, double-walled pipe. The outer pipe draws fresh air in while the inner pipe exhausts combustion gases. This configuration reduces wall penetrations and simplifies installation.

Concentric vents are common on condensing tankless water heaters. Using a single penetration lowers material and installation costs and improves aesthetic integration into your home’s exterior. This system ensures a balanced ventilation process while protecting the vent from external damage.

Common Venting Applications

Common venting applies when multiple appliances share one ventilation path. Although often used in traditional water heater setups, it’s less common for tankless systems due to their unique combustion and exhaust requirements.

If you consider common venting, confirm compatibility with your tankless unit, as improper venting can risk carbon monoxide buildup. Due to complexities, this type of venting is best handled by a professional. For expert advice on venting solutions tailored to your home, Splash Plumbing can guide you through safe and code-compliant options.

Each venting system affects installation decisions, so understanding these types helps you make the best choices for performance and safety in your home or business.

Selecting the Right Venting Option

When installing your tankless water heater, choosing the appropriate venting system impacts both safety and efficiency. Each venting option has specific requirements depending on your unit type, installation location, and fuel source. Understanding these elements will help you make an informed decision.

Venting Options for Indoor and Outdoor Models

Indoor tankless water heaters typically require sealed venting systems that draw combustion air from outside and expel exhaust outdoors. You can choose between direct-vent (balanced) and power-vent systems. Direct-vent uses a two-pipe system, reducing the risk of backdrafting, while power-vent relies on a fan to push exhaust through the vent. Power-vent models need electricity but offer more flexibility in vent placement.

Outdoor models usually have simpler venting because they vent directly to the atmosphere without pipes. These units reduce installation costs but must be built to withstand weather and temperature variations. If venting options are limited due to building codes or location, outdoor units can be a practical alternative.

Choosing Between Condensing and Non-Condensing Units

Condensing tankless water heaters extract more heat from exhaust gases, improving efficiency by up to 10–20%. They require stainless steel or plastic vent pipes to handle corrosive condensate and must be vented vertically or horizontally with proper slope for drainage. Condensing units are ideal if you want to reduce greenhouse gas emissions and lower fuel costs.

Non-condensing units vent hotter exhaust safely through metal pipes, often requiring vertical venting through a roof. These systems tend to have simpler vent installation but are less efficient. If your system uses propane or natural gas, condensing models can save energy but need more careful vent design to manage moisture.

Factors Affecting Vent System Selection

Fuel type plays a key role in vent selection. Gas-powered and propane tankless water heaters generate combustion gases that need safe venting outside to prevent carbon monoxide buildup. Your local building codes and manufacturer instructions will specify acceptable vent materials and clearances.

The vent’s length and routing affect both performance and installation cost. Longer or complex vent runs may require power venting to ensure proper exhaust flow. Also, space constraints and access to exterior walls influence vent choice. Clearance around the vent is essential for proper airflow and maintenance.

If you’re unsure about your home’s venting needs, consult professionals like Splash Plumbing. Serving Anaheim and Orange County, they can evaluate your setup and recommend the safest, most efficient venting option for your tankless water heater.

Step-by-Step Guide to Venting a Tankless Water Heater

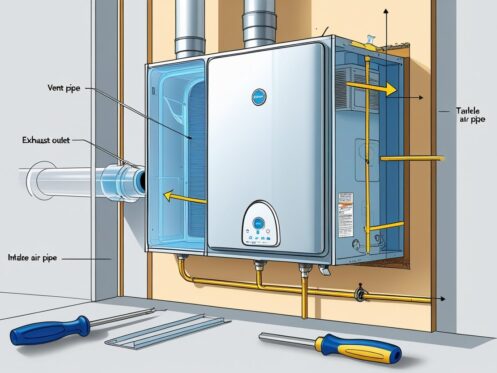

Venting a tankless water heater requires choosing the proper venting materials, planning the vent path carefully, and correctly joining and sealing the vent pipes. You must follow manufacturer guidelines for vent pipe size and position to ensure safety and efficiency.

Planning the Vent Route

Start by locating your tankless water heater and identifying the shortest, most direct path to the outside for venting. Avoid long runs or sharp bends, as these reduce efficiency and can cause vent blockages.

Identify whether horizontal or vertical venting fits your space better. Check local codes and manufacturer specs for minimum clearances and vent pipe materials suitable for your heater’s fuel type. Make sure there is enough clearance around the vent termination to prevent exhaust re-entering your home or your neighbors’ spaces.

You should also consider the distance from windows, doors, and air intakes. Installing a vent adapter where the heater connects to the vent pipe ensures compatibility and a secure fit during this planning stage.

Installing Horizontal Venting

Horizontal venting typically expels exhaust through a nearby exterior wall. Use vent pipes made of corrosion-resistant materials, ideally approved stainless steel or special vent pipe rated for tankless units.

Begin with a vent adapter attached to the heater’s exhaust outlet. Then, run straight vent pipe sections toward the outside, maintaining a slight upward slope of about 1/4 inch per foot to prevent condensation buildup inside the pipe.

Secure vent pipes firmly with brackets or straps every few feet to avoid sagging. Use proper termination caps designed to keep out debris and pests while allowing exhaust gases to exit freely.

Installing Vertical Venting

Vertical venting vents exhaust upward through the roof or an upper wall. This method uses natural buoyancy of hot exhaust gases to exit the building.

Attach the vent adapter to the heater first. Then run vent pipes straight up, ensuring all joints slope upward and are tightly connected. Install a vent pipe support system to hold vertical vent pipes securely, preventing movement and leaks.

At the roof penetration, use proper flashing and a vent cap to prevent water infiltration and to allow safe discharge of exhaust gases. Check that the vent extends beyond the roofline as required by code, typically several feet, for proper draft and safety.

Connecting and Sealing Vent Pipes

Connections between vent pipes must be airtight to avoid exhaust leaks. Use high-temperature-rated sealants or approved vent pipe tape at every joint.

Secure all connections with mechanical fasteners like sheet metal screws; avoid using nails or adhesives that can degrade under heat.

Before sealing, test the system for tightness and correct slope. Proper sealing ensures that combustion gases do not escape into living spaces, protecting your home and maintaining your tankless water heater’s efficiency.

If you prefer professional assistance or live near Anaheim, CA, Splash Plumbing offers expert venting installation and inspection to ensure your system meets all safety standards.

More detailed guidance on venting options and materials can be found at How to Vent a Tankless Water Heater: A Comprehensive Guide.

Installation Best Practices and Safety Guidelines

Proper installation of your tankless water heater vent system is essential to ensure optimal performance and safe operation. Attention to local codes, fire safety, and avoiding venting issues protects your home from hazards while maintaining system efficiency.

Ensuring Code Compliance

You must follow all local building and plumbing codes when installing your venting system. These regulations dictate vent pipe materials, maximum lengths, clearances, and termination points to ensure safety and efficiency. Using approved vent components and proper sealing prevents leaks and condensation buildup.

Before installation, check for any city-specific requirements regarding the vent type—whether concentric or separated pipes—especially when dealing with gas-powered units. Failure to comply can result in safety violations or poor heater performance. When in doubt, working with a qualified professional like Splash Plumbing helps ensure your system meets all code requirements.

Fire Safety and Clearances

Maintaining appropriate clearances around your vent pipes is crucial for fire prevention. Keep vents away from combustible materials such as wood, insulation, or drywall. Usually, a minimum clearance of 1 to 3 inches is required, but verify this based on your vent and heater model.

Use listed vent pipe insulation or shield kits where needed to prevent heat transfer to nearby surfaces. Proper vent placement also protects soffits, eaves, and windows from heat exposure or exhaust gases. Ignoring clearance guidelines increases the risk of fire or damage to your home’s structure.

Preventing Backdrafts and Leaks

Backdrafts occur when combustion gases fail to exit properly, potentially introducing carbon monoxide into your living space. You can prevent this by ensuring vent terminations are correctly placed with adequate fresh air intake and no obstructions.

Check all vent joints for tight seals using approved materials and inspect for cracks or corrosion regularly. Improper vent sloping or damaged pipes can cause leaks or water intrusion, which harms your heater’s efficiency. Consistent vent system maintenance is key to avoiding these safety risks and prolonging your tankless water heater’s lifespan.

For expert installation and maintenance, Splash Plumbing offers professional services tailored to your home in Anaheim, CA, ensuring your tankless water heater venting remains safe and effective. For more detailed venting techniques, consult a guide on tankless water heater venting best practices.

Maintenance and Troubleshooting for Vent Systems

Proper care of your tankless water heater’s vent system ensures safe operation and extends its lifespan. Regular checks prevent blockages and damage, while timely repairs address any malfunction. Knowing when to call a professional can save time and avoid costly hazards.

Regular Inspection of Vent Components

Inspect your vent pipe and related components at least twice a year. Look for signs of corrosion, rust, or holes that could allow exhaust gases to leak inside. Check the vent cap for any debris or nests blocking airflow.

Monitor the seals and joints between vent sections for cracks or looseness. Even a small gap can reduce efficiency or pose safety risks. Pay special attention after storms or high winds, as vents may shift or loosen.

You can clean debris from the exterior vent cap with a brush or vacuum. Never attempt to clear blockages inside without professional tools and expertise, as improper handling might cause carbon monoxide buildup or damage to your unit.

Addressing Common Vent Issues

If you notice irregular hot water supply, unusual odors, or excessive condensation near the vent, these could indicate vent problems. Restricted airflow or damaged vent pipes can cause your tankless water heater to shut down or operate inefficiently.

Listen for unusual noises like whistling or rattling, which may signal loose vents or obstructions. Cracks or rust often develop on metal vent pipes exposed to moisture, requiring immediate attention to prevent further damage.

Some common fixes include tightening vent connections, replacing damaged pipe sections, or clearing minor obstructions from the vent cap. However, avoid DIY repairs that involve dismantling vent pipes or adjusting the burner system.

Professional Maintenance Recommendations

Engage a certified technician, such as the experts at Splash Plumbing, to perform a thorough vent system inspection and cleaning annually. They have the tools to safely check inside vent pipes and test for carbon monoxide leaks.

Professional service includes clearing internal blockages, verifying correct vent configuration, and repairing or replacing damaged parts to meet safety codes. This ensures your tankless water heater operates at maximum efficiency and complies with local regulations.

Regular professional maintenance also helps identify early signs of wear or improper installation before they become serious problems. If you are near Anaheim, CA, Splash Plumbing offers reliable vent system servicing tailored to your tankless water heater’s needs.

Frequently Asked Questions

Proper venting of your tankless water heater involves meeting local codes, choosing the right vent components, and deciding between roof or exterior wall venting. Vent distance limits and detailed installation methods are critical to ensure safety and performance.

What are the code requirements for venting a tankless water heater?

Venting must comply with local building and safety codes, which typically reference national standards such as the International Residential Code (IRC) or manufacturer guidelines. You must use approved vent materials and ensure proper clearances from windows, doors, and combustible surfaces.

Can you provide a venting diagram for a tankless water heater installation?

Venting diagrams vary based on your unit’s model, fuel type, and installation location. Most manufacturers provide specific diagrams in their manuals. If you need a custom diagram, a professional plumber can create one tailored for your setup, ensuring all safety and efficiency requirements are met.

What is the maximum venting distance for a tankless water heater?

Maximum vent lengths depend on the diameter and type of vent pipe, the number of elbows, and the model specifications. Typically, vent distances range up to 30-40 feet, but too long or improperly routed vents can reduce efficiency and safety. Always check your heater’s manual for exact limits.

What components are included in a standard tankless water heater vent kit?

A standard vent kit usually contains vent pipes, elbows, vent caps, pipe supports, and sealing components. Some kits include both air intake and exhaust pipes, especially for direct vent models. Using the right kit helps maintain proper airflow and prevents leaks.

How do you properly vent a tankless water heater through the roof?

Roof venting requires angled flashing to seal around the pipe, ensuring no water entry. The vent must extend above the roofline per code, with proper distance from air intakes or windows. Supporting the vent pipe to withstand wind and weather is essential for long-term stability.

What are the considerations for venting a tankless water heater through an exterior wall?

When venting through a wall, the vent must terminate at a safe clearance height, away from windows, doors, or other openings. Wall vent caps should prevent water and pests from entering. Clear air intake is necessary to maintain combustion efficiency without drawing indoor air.

If you require expert installation or guidance, Splash Plumbing offers experienced service in tankless water heater venting to help you meet all safety and performance standards.